Can Rigid Flex Circuits Bend Or Twist?

Rigid Flex Circuits Bend Or Twist

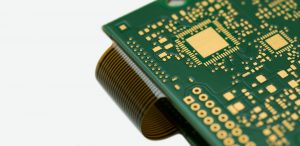

Rigid flex circuits are an innovative and effective way to design electronic devices. They combine rigid and flexible substrates, making them a game-changer in applications that require both stiffness and dynamic adaptability such as wearable technology, aerospace technology and medical equipment. During this webinar, we’ll examine the best practices for designing and manufacturing rigid-flex PCBs while exploring industry-recognized methods for achieving a robust and efficient product.

The rigid-flex PCB production process is complex, and it begins with the development of clear goals and specifications for the final project. This will influence the choice of materials and other factors that make up the finished product. It is also important to consider the surrounding environment and whether or not the device will have to withstand repeated bending or flexing. Once the goals and specifications are established, engineers or PCB manufacturing designers can begin to design the flex circuit board.

During the manufacturing process, the flex circuits are etched using either a mechanical or chemical method. The etching process removes the insulating layers and exposes copper that is then plated through holes in the rigid-flex PCB. The plated copper forms the circuit connections between the rigid and flex sections of the board. Finally, the coverlay layer is applied to protect the circuits and reduce electromagnetic interference (EMI). The most common coverlay material is additional polyimide film with adhesive, though an adhesive-less process is available. This coverlay is typically printed using a photo-imageable solder mask, similar to that used on rigid board sections. For coarser designs, screen printing is also possible.

Can Rigid Flex Circuits Bend Or Twist?

Once the rigid-flex circuits have been fabricated, they are tested for integrity and reliability. This testing may include measuring the thermal expansion of both rigid and flex sections to ensure that they remain stable in a wide temperature range. It is also important to measure the impedance between rigid and flex sections of the board to ensure that it remains consistent.

The best way to guarantee that a rigid flex circuits can be bent or twisted without damaging the conductors is to ensure that the flex section has a large enough bend radius. For one- and two-layer flex circuits, the minimum flex radius should be six times the thickness of the flex component. For three-layer or higher flex components, the minimum bend radius should be 12 times the thickness of the flex composite.

Rigid-flex circuits are an innovative and cost-effective way to design and manufacture cutting-edge electronic devices that demand both stiffness and dynamic adaptability. They are ideal for applications that need to operate in environments with high temperatures or frequent movement, such as wearables and aerospace technologies. They can also increase the dependability and durability of devices that need to transmit sensitive signals at high speeds. However, when designing a rigid-flex circuit, it is important to keep in mind that the impedance of the rigid and flex portions of the board can change over time due to the different stack-ups. This can impact signal quality and stability.